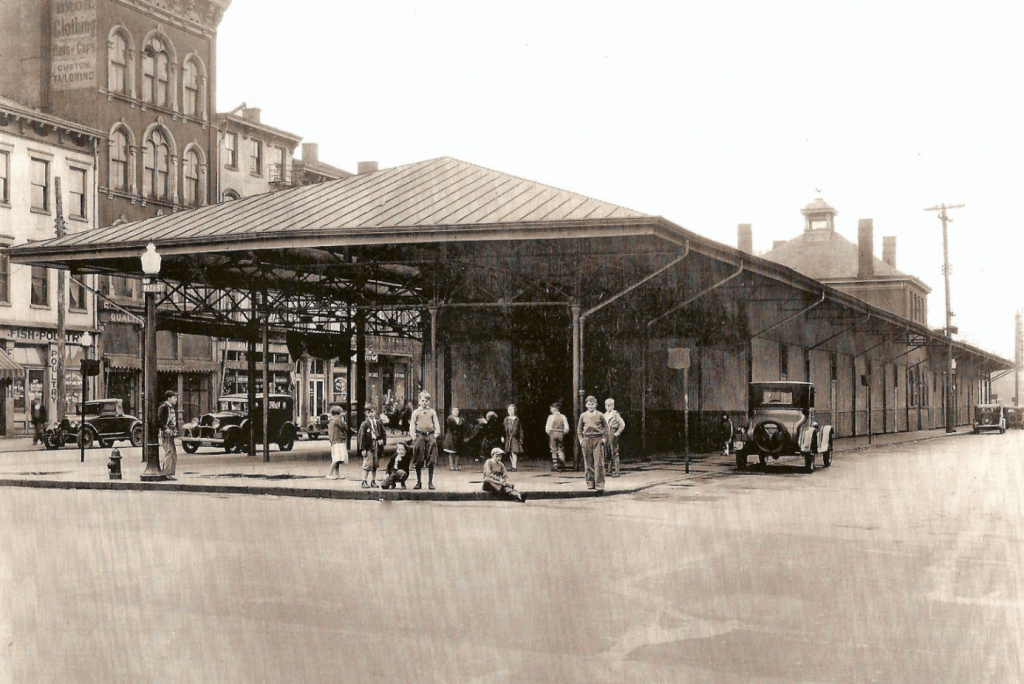

Findlay Market 1921

The market revolution shifted American work focus from producing for yourself to producing to sell to others. Prior to the mid 19th century Americans were already producing products to sell to others but the market revolution brought about a few significant changes. First the scale of producing and selling increased significantly and second the distance these products would reach greatly expanded. As the market gained success new technologies were created that further increased the efficiency of this system. However, this process was not beneficial for all. While this system allowed some people to gain wealth, for many working for someone else as a laborer came with its own challenges. Meat packing facilities especially posed various dangers due to the complex machinery used to create the meat cuts and hog by-products.

The creation of the factory changed the pork industry. The factory was an organizational innovation in creating an efficient way to process pork and by-products quickly. A multitude of technologies aided the rise of the pork industry’s success. Pork packers were constantly seeking ways to more efficiently slaughter hogs and transform parts into commodities. Technologies like the assembly line, hooks and gambrels, the lard rendering tank, and the refrigerated railroad kart added to the profitability of the pork industry. The assembly line factory set up was created in the 1830’s and continued to be improved upon throughout the 19th century. This development allowed all stages of production to occur in a single location. Almost all meat products from the hog were prepared for market in these plants. While by-products such as soap, candles, and brushes were taken to a different location to be manufactured. A specific technology created for the assembly line was the hook and gambrels. Created in 1840 the hook and gambrels made the transportation of slaughtered hogs more efficient by using hooks attached to the hogs’ hind legs high off the ground attached to a system of gambrels to move the heavy animal body.Another invention was the refrigerated railroad cart by William Davis in 1867 which further expanded the industry’s options. The refrigerated railroad impacted how far and for how long fresh pork could be transported, without needing to be altered via salting.

Technological developments were also made for the harvesting of parts for by-products. The lard rendering tank was created in 1844 by a Cincinnati meatpacker named Ebenezer Wilson. Through the steam, lard oil and prime lard were successfully separated, as a replacement for sperm oil. By 1843 lard was the most important pork product, of the 245,000 hogs killed in Cincinnati to date that year, 80,000 had been killed for the express purpose of conversion to lard using a new technique of steam rendering. The Berkshire and Poland China hogs yielded as much as 70 percent lard recovered. Once the lard was rendered it was used to create products, two examples were soap and candles. In 1837 two immigrants, William Procter, an English storekeeper and candle maker, and James Gamblean Irish soap maker joined their businesses to create an empire of lard commodities. This company is known as Proctor and Gamble.

Meat products remained popular as well. Bacon was used as a generic term to describe all meats that were salted or smoked. Ham was separated into three grades; clear, mess, and prime. Clear was the highest quality made from the hog with the highest fat content. Mess pork mainly included the ribs and rump of the hog. By 1870 mess pork cost nine dollars a barrel and a pound of lard cost six cents. Prime pork consisted of the leanest cuts and were considered low quality due to their lack of fat.

Findlay Market

During the 19th century public markets were centers for the buying and selling of food products. These large markets were especially popular in cities where fresh produce and meats were needed. Of these Cincinnati markets Findlay Market is the only one still standing today. Findlay Market was established in 1852 by James Finley. To this day it still operates as Ohio’s oldest public market. Finley was originally from Pennsylvania but in 1793 he opened a store at the base of the Ohio River. As he gained wealth he opened larger stores and eventually the Findlay Market in 1852. The market is near the over the Rhine neighborhood.

The architecture of Findlay Market was designed by the City Civil Engineer Alfred West Gilbert. He used a strong long lasting cast and wrought iron frame. This material was a new construction technology, one of the first markets in the United States to use an iron frame. Throughout the decades further improvements and upkeep have kept Findlay Market in working condition. In 1972, Findlay Market was placed on the National Register of Historic Places list.

Eckerlin Meats

Eckerlin’s Meats has been a part of Cincinnati since 1852. In 1855 it set up a storefront with the Findlay Market. Ernie Eckerlin was the founder of Eckerlin’s Meats, he was from Baden, Germany and started the business when he came to Cincinnati with his family. Originally Eckerlin’s Meats was a Cincinnati slaughterhouse. However, as the business grew more successful Ernie expanded his operation to include a stand at Findlay Market. The business has remained in the family and is currently run by the fifth generation to run Eckerlin’s Meats.

Court Street Market

Court Street Market was built in 1864 on Court Street; it was located between Vine Street and Walnut Street. There was a market at this location since 1829 called Canal Market, a name that came from the Miami Canal which was in close proximity. There was a stone tunnel built to move hogs between the various slaughterhouses near Court Street. This tunnel ran under the market.